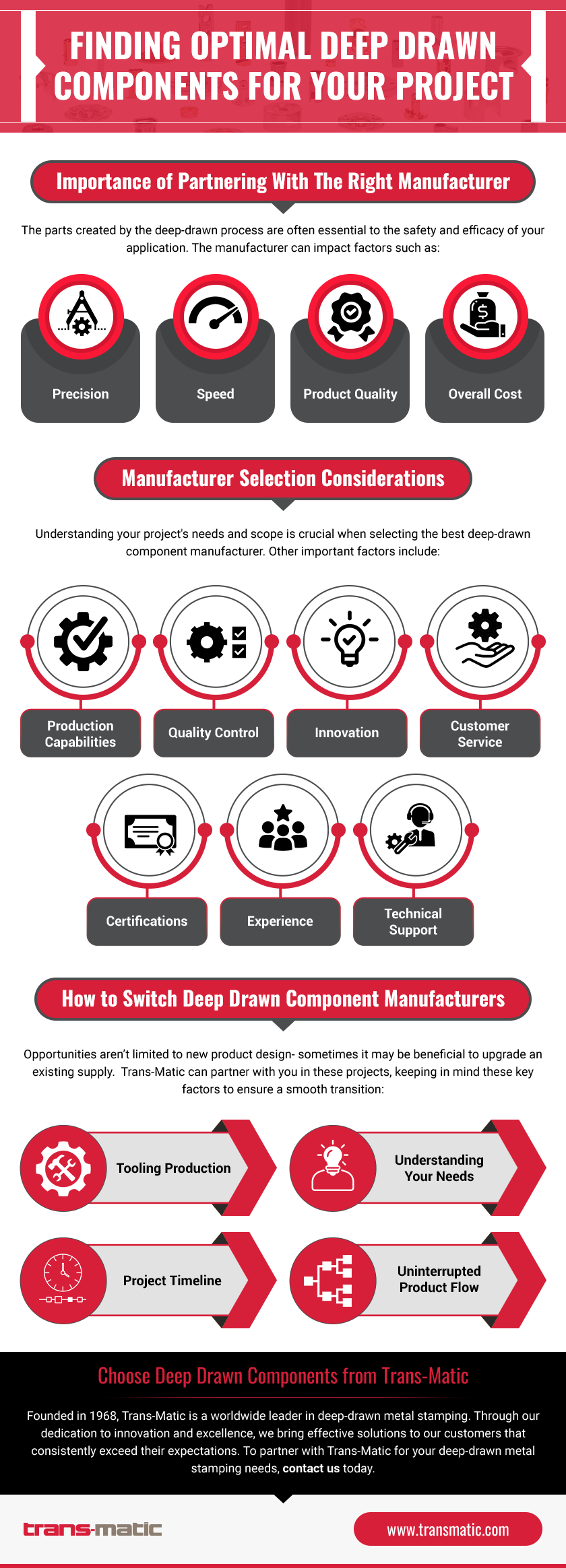

Importance Of Partnering with The Right Manufacturer

The parts created by the deep-drawn process are often essential to the safety and efficacy of your application. The manufacturer can impact factors such as production speed, product quality, and overall cost of your product; therefore, it is crucial to partner with a deep-drawn component manufacturer that is reliable and experienced. The right manufacturer will work in tandem with your company to provide the needed parts efficiently and with optimal quality.Manufacturer Selection Considerations

Understanding your project’s needs and scope is crucial when selecting the best deep-drawn component manufacturer. Other important factors to consider include:Production Capabilities/Capacity

Your deep-drawn metal stamping manufacturer should have the necessary tools, skills, and facilities to meet your needs in terms of production volume, design, and materials. They should also be able to create components in-house based on your specific standards and specifications. If you are looking to partner with them long-term, be sure they can adjust their operations to keep up with decreasing or increasing demand.

Quality Control

One of the best ways to determine whether a deep-drawn component manufacturer is right for your needs is to take a look at their quality control procedures. Their quality control standards should align with yours, and they should have the right processes and equipment to ensure your products meet them.

Innovation

The manufacturing industry is very competitive. This means companies must show their willingness to invest in new and up-to-date technologies to ensure they can keep up with growing demands and give their customers quality products. The right partner should express a dedication to innovative manufacturing processes and continuous improvement.

Customer Service

The right manufacturing partner should have a strong grasp of your needs. They should maintain a strong line of communication, have quick response times, and be open to working with you to create the best possible manufacturing solution for your needs.

Certifications

If your particular application or industry is subject to specific standards, your deep-drawn component manufacturer should be capable of delivering products that adhere to those standards. For example, if you work in the aerospace industry, your manufacturer should be AS9100D-certified and deliver products that comply with that standard’s guidelines.

Experience

With many manufacturing partners to choose from, looking into a company’s history and experience can help you narrow down your options. Working with a company with a long history increases the chances that they’ve produced similar parts to what you require. Experienced manufacturers can provide valuable design feedback and offer suggestions to ensure successful production. Experienced manufacturers also tend to offer more services in-house, such as prototyping, annealing, and more, which can save you time and money.

How to Switch Deep Drawn Component Manufacturers

Once you have determined the ideal deep-drawn component manufacturer, there are some key tips to keep in mind to ensure a smooth transition:- Tooling production. If you don’t already own the necessary tooling for your projects, you will need to incorporate the cost of producing new tooling into your budget.

- Understanding your needs. Make sure your new manufacturing partner has a firm grasp of your tolerance requirements, desired applications, and material needs.

- Timeline. Perform a test run with your new partner to ensure they can finish your projects according to your timeline.