Deep drawn stamping is an efficient process that can save your business both time and money when it comes to manufacturing a large volume of products. Traditional manufacturing techniques just can’t compare to the highly effective process of deep drawing, and the final results are of higher quality as well. Trans-Matic has decades of experience in deep drawing techniques and the company’s toolmakers and engineers have become a global supplier of deep drawn products.

Deep drawn stamping is an efficient process that can save your business both time and money when it comes to manufacturing a large volume of products. Traditional manufacturing techniques just can’t compare to the highly effective process of deep drawing, and the final results are of higher quality as well. Trans-Matic has decades of experience in deep drawing techniques and the company’s toolmakers and engineers have become a global supplier of deep drawn products.

Deep Drawing

Deep drawing is a unique process that involves using metal dies to transform blank sheets of metal into unique shapes that can then be mass-produced. Deep drawing is a very efficient process that produces exceptional results that can’t be achieved with traditional methods. Since it’s a process of repetition, deep drawn parts are able to be created more efficiently and at higher volumes, costing much less than you’d spend using other methods. In fact, once you’ve created the tooling and dies, your parts can be manufactured at a high velocity. The more parts you produce, the less they’ll cost, since your biggest expense lies in creating the initial tooling and dies.

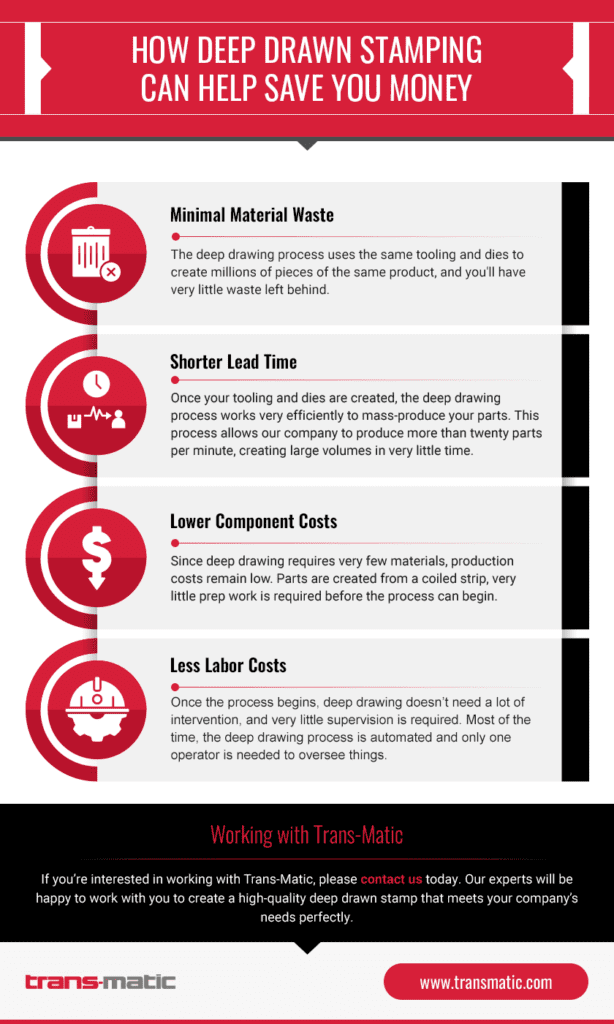

Deep Drawing Reduces Costs

Companies choose deep drawing because of its many advantages, but one of the greatest benefits in selecting this process lies in its cost-effective technique. When you use a deep drawing process to produce parts for your company, you’ll significantly reduce manufacturing costs, allowing you to allocate that money elsewhere. Below are a few of the ways the deep drawing process can save your business money when you use it rather than traditional manufacturing processes.

Minimal Material Waste

The deep drawing process uses the same tooling and dies to create massive amounts of the same product, and you’ll have very little waste left behind. Traditional manufacturing techniques aren’t nearly as efficient, and they use more material to produce the same results, costing your company more in the process.

Shorter Lead Time

Once your tooling and dies are created, the deep drawing process works very efficiently to mass-produce your parts. This process allows our company to produce more than twenty parts per minute, creating large volumes in very little time. Traditional manufacturing processes have much longer lead times and they’re far less efficient at mass-producing high-quality parts.

Lower Component Costs

Since deep drawing requires very few materials, production costs remain low. Parts are created from a coiled strip, and as long as everything’s clean and compliant with the specifications needed, very little prep work is required before the process can begin. This allows us to charge far less than traditional manufacturers for superior results.

Less Labor Costs

Once the process begins, deep drawing doesn’t need a lot of intervention, and very little supervision is required. Most of the time, the deep drawing process is automated and only one operator is needed to oversee things.

Applications of Deep Drawn Stamping

Deep drawn stamping is a technique that is used to manufacture a variety of products you’d recognize in your home and everyday life. Some common products that were created through the deep drawing process include:

● Kitchen Sinks

● Fire Extinguishers

● Baking Pans

● Solenoids

● Assembly Housings

● Aluminum Cans

● Tire Rims

● Lighting Assemblies

● Lawn Mower Decks

Many companies take advantage of the deep drawing process to achieve efficient and cost-effective results for their products.

Working with Trans-Matic

Since 1968, Trans-Matic has been creating high-quality deep drawn metal products for businesses across the globe. The company’s expert toolmakers and engineers work diligently to design precise, cost-effective solutions for its customers at its state-of-the-art facility in western Michigan. Trans-Matic prides itself on being innovative and customer focused. They provide individualized solutions for each business partner. If you’re interested in working with Trans-Matic, please contact us today. Our experts will be happy to work with you to create a high-quality deep drawn stamp that meets your company’s needs perfectly.